In both biology and technology, intelligence advances through connection and experience, not by starting over each time. Yet intelligence alone is not enough to guarantee longevity. Take the octopus for example. It is one of the most intelligent creatures on Earth, capable of solving puzzles and using tools, yet its lifespan rarely exceeds three to four years. Its brilliance dies with the individual, leaving only species-level instinct to carry the torch.

Like the octopus, the automotive industry often limits its own intelligence cycle. Frequent supplier changes force OEMs to reintegrate complex software, erasing hard-won expertise and making each project feel like starting over.

This constant reinvention is costly. It is estimated that around $2000 per car is spent on software development. Interviews with industry experts suggest that the share of software spending dedicated to innovation can be as low as 5–10%, with the remainder devoted to integration, maintenance, and supplier realignment. In other words, most of today’s software investment sustains what already exists rather than advancing what’s next.

The result is a cycle of short-lived intelligence, rather than sustainable growth. The question is not only how to be smarter, but how to preserve what has already been learned.

So how can OEMs evolve beyond this pattern and build a truly sustainable software-defined vehicle (SDV) without breaking the bank? Or rather, how can OEMs evolve to build the right-sized SDV?

Building the right-sized SDV without breaking the bank

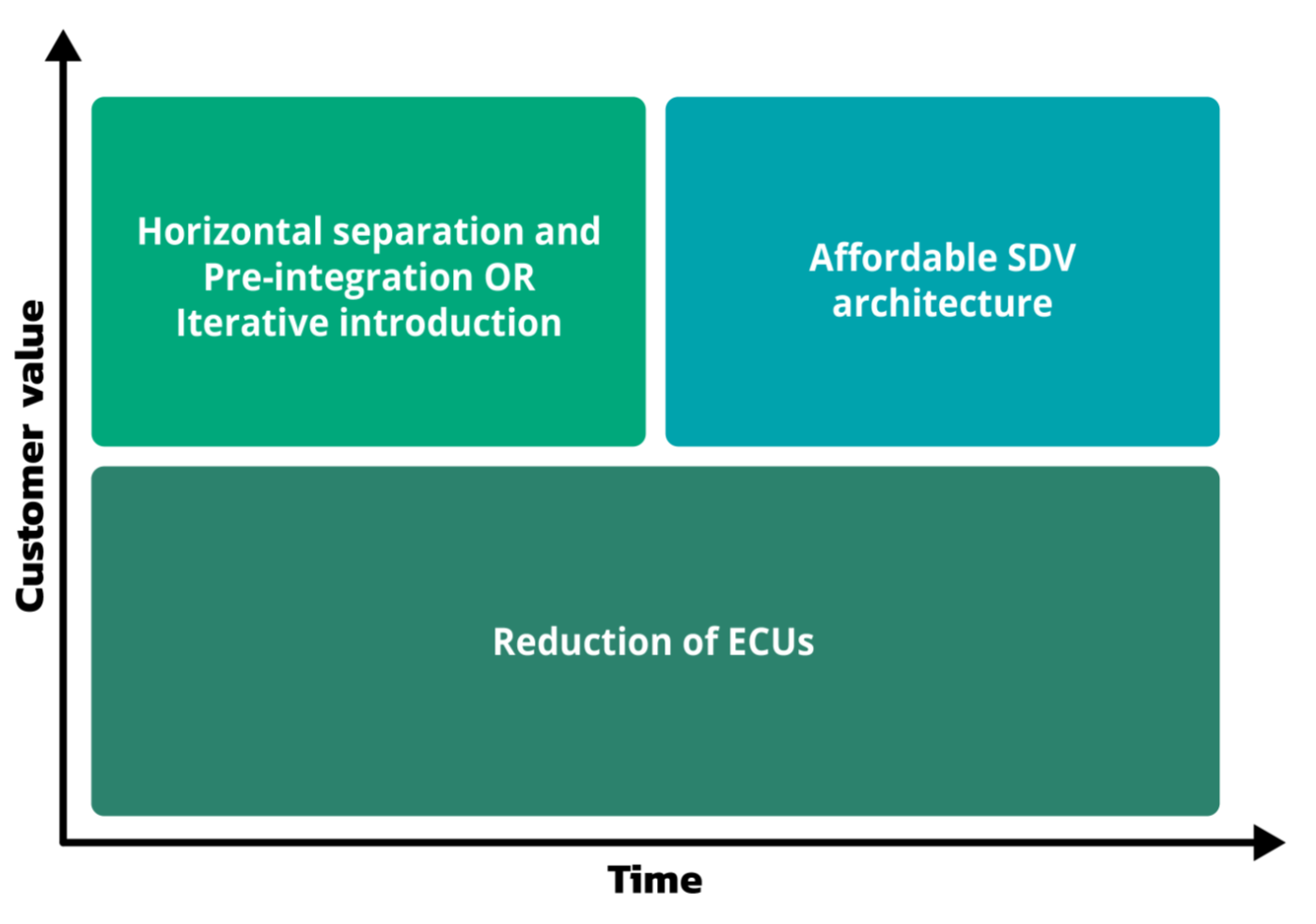

Reduction of ECUs

Most OEMs begin with what can be achieved immediately, focusing on reducing the number of ECUs and simplifying their architectures. This can yield some short-term savings and efficiency gains, but it is not a long-term fix. The same approach can be carried into future vehicle generations, yet it remains fundamentally tactical rather than strategic. Progress made today is too often erased when new partners arrive.

For instance, Rivian’s early consolidation of ECUs demonstrates the potential efficiency of this approach, though it is yet to be shown how this scales for a larger set of car models with a broader spread from entry to luxury.

Affordable SDV architecture

The real transformation begins when OEMs base their development on a right-sized SDV strategy and architecture. This is where Elektrobit’s long-term approach comes in. The goal is not just to modernize, but to enable sustainable, scalable innovation across the entire vehicle portfolio lifecycle. This is how intelligence learns to persist; by remembering, by building upon itself rather than starting over again.

This vision is built on three pillars:

- High-frequency upgrades on IVI systems – these have a direct impact on the end user experience, since the IVI is always in front of their eyes. Platform updates can happen frequently without code changes. Interface and application enhancements can also roll out faster, using fewer hardware options for greater consistency and speed.

- Software platform with frequent fleet upgrades – achieved through a semantic API that allows systems to exchange information consistently, even as hardware changes. This separation of the software platform from applications simplifies upgrades and preserves interface stability across hardware and software generations.

- Fully flexible zone architecture – by moving functional software to central compute and retaining only the software needed for physical actuation, paired with a plug-and-play mechanism, OEMs can reuse hardware and software across the platform with full scalability.

These three pillars represent a clear long-term path, but they are still perhaps five years away for most OEMs. The key question, then, is how to start moving in that direction today, how to take the first steps toward a memory that spans generations.

Horizontal separation and pre-integration or iterative introduction

A strategic path forward starts now with the gradual, step by step introduction of a right sized SDV architecture. Change does not need to be radical to have an impact. Even small and deliberate adjustments generate real and measurable value.

To make this concrete, consider doors as a single feature domain. By moving door logic from multiple local ECUs into a shared compute environment and eliminating redundant hardware, a budget segment car can save roughly 15 euros per vehicle compared to a conventional non optimized topology. That is one feature group on one platform. The cumulative effect scales across additional domains and trims once the same patterns are applied.

The goal is not to impose a one-size-fits-all model but to create an SDV solution tailored to each OEM’s product and market strategy. For teams looking to accelerate progress, horizontal separation and pre-integration offer a practical entry point. Think of it like moving into a pre-built house. It may not match every preference immediately, but it provides a strong foundation that can expand over time.

In practice, this approach involves:

- Designing hardware around a unified set of central ECUs instead of creating one per supplier

- Separating production from hardware design, and hardware design from the software platform

- Using a semantic API to clearly divide the software platform from its applications, ensuring flexibility and stability across vehicle generations

This is not theory. Foxconn, in collaboration with Elektrobit, is already putting this approach into action. Together, we are modernizing vehicle software while building an ecosystem that learns, retains knowledge, and grows over time, ensuring intelligence compounds rather than resets with each new project.

Choosing your evolution

There are paths for every level of readiness. The decision depends on how much you want to save, how much of the result do you want to own, and how far you want to go into the SDV journey over the next three to five years.

Focusing on reducing ECUs can deliver immediate savings and can be applied in future programs, but it also limits the value you deliver to customers, which reduces long-term sustainability and competitiveness. An affordable SDV architecture can unlock major benefits, although it requires significant investment and a strategic plan that pays off over time. A horizontal separation approach, paired with pre-integration or an iterative introduction strategy, offers the strongest balance between near-term progress and high customer value.

Elektrobit already provides solutions to support this middle path, whether through iterative introduction or horizontal separation and pre-integration. Like the octopus example above, intelligence alone is not enough. Survival depends on the ability to pass that intelligence forward, to preserve memory across cycles, to let knowledge compound instead of reset.

Whether biological or technological, the path to sustainable intelligence lies in memory, not reinvention. The right-sized SDV is the first step toward a vehicle that not only learns, but remembers.