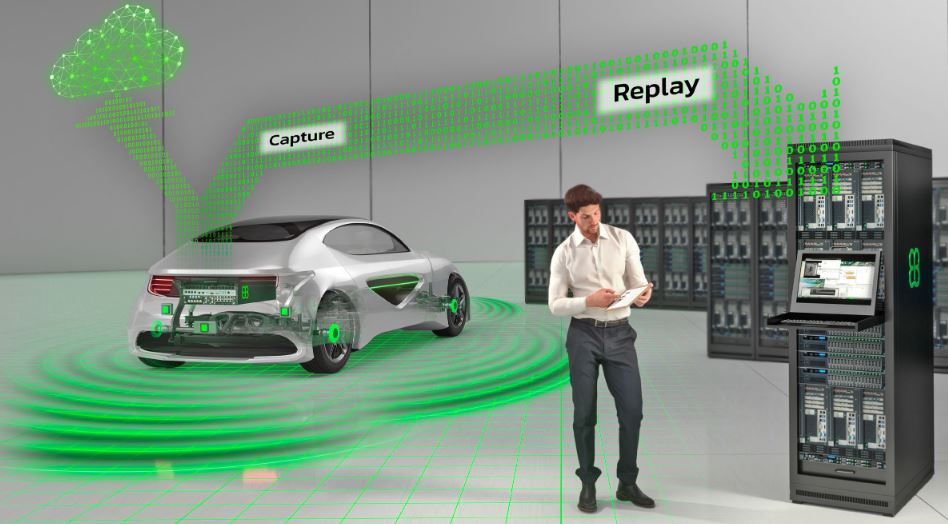

Scalable & modular flexible systems for logging sensor data

With EB Assist Logger Solution you will be able to accurately record your vehicle sensor data like video (e.g. with EBX3 card: GMSL2/FPD3/GVIF) or bus communication (e.g. with EBX3 card: 2.5 GBASE-T1, Automotive Ethernet, CAN/CAN-FD, Flexray, DSI3, GPS) in a time synced way.

Benefit from high-performing, reliable automotive PC system to suit your testing and validation needs in multiple plattforms (e.g., ADAS, IVI, HMI…).

More than 1700 data loggers are in use within multiple mobile platforms. Elektrobit offers from small variants (e.g. 2wheeler) up to high variants (up to 32GB/s data rates / 500TB storage).

Smart Logging to reduce the amount of data up to 100x : with our AI solution you are able to use object triggers to start, stop your recording and to label them live automatically while driving. Further more you will be able to compress the data lossless.

TAP/By-Pass mode: No side effects in the overall system. Capture the data between your sensors and the ECU.

Scalability: High processing power allows capturing of multiple sensor streams in parallel.

You can easily combine multiple logger systems to scale your system for video or bus data capturing.

High-performance: CPUs and a customized system for different use cases (low, mid, and high variant).

HMI development & validation: with our Image Solution Box you are able to capture and stimulate display / HMI ECUs.

Customized solutions: we are developing the bus measurement devices (> 10.000 pieces) by our self and customize new modules/interfaces for your needs.

Ready-to-use system: with our modular and reusable concept we have low costs & fast delivery times.

Supported Data Formats –

ARXML

ASC

A2L

CSV

DBC

Fibex

MDF

PARQUET

PCAP / PCAPNG

Video (avi, mkv, …)

Improve the quality of data logging

Highly precise time stamping on hardware at a resolution of 25 ns. Logging multiple data in a time synced way (video & bus data). Detachable storage up to 500TB / 32GB/s.

Save time and money during development and validation

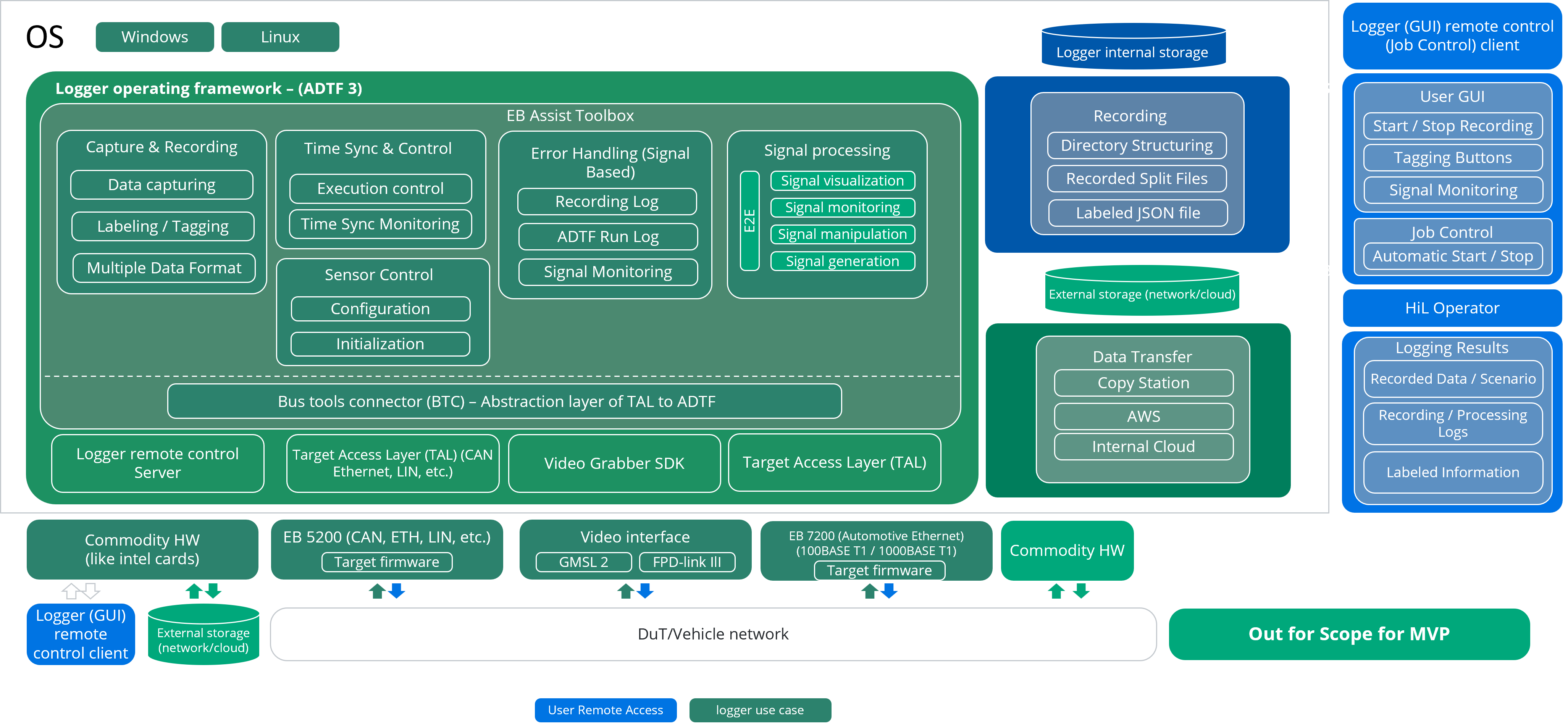

Our high-performing and reliable automotive PC system integrates easily with EB Assist bus tools and EB Assist ADTF.

Customizable turnkey solution

Our in-house hardware and firmware development enables a fast and flexible realization of your requirements with a highly flexible I/O configuration (e.g. capturing large amounts of synchronized video and bus data, extension of storage or PCI-e interfaces).

Delivery and support from one single source

One single contact ensures complete and professional support with short response times during your buying and configuration decision and beyond.

Field & effort reduction with Smart Logging

Reduce the amount of your test drives and test data up to 100x.

Key features of the EB Assist

Logger Solution hardware

series at a glance

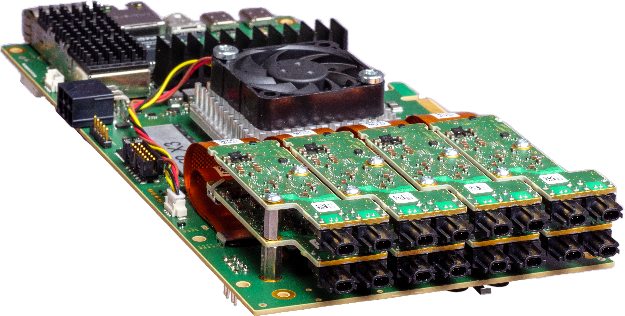

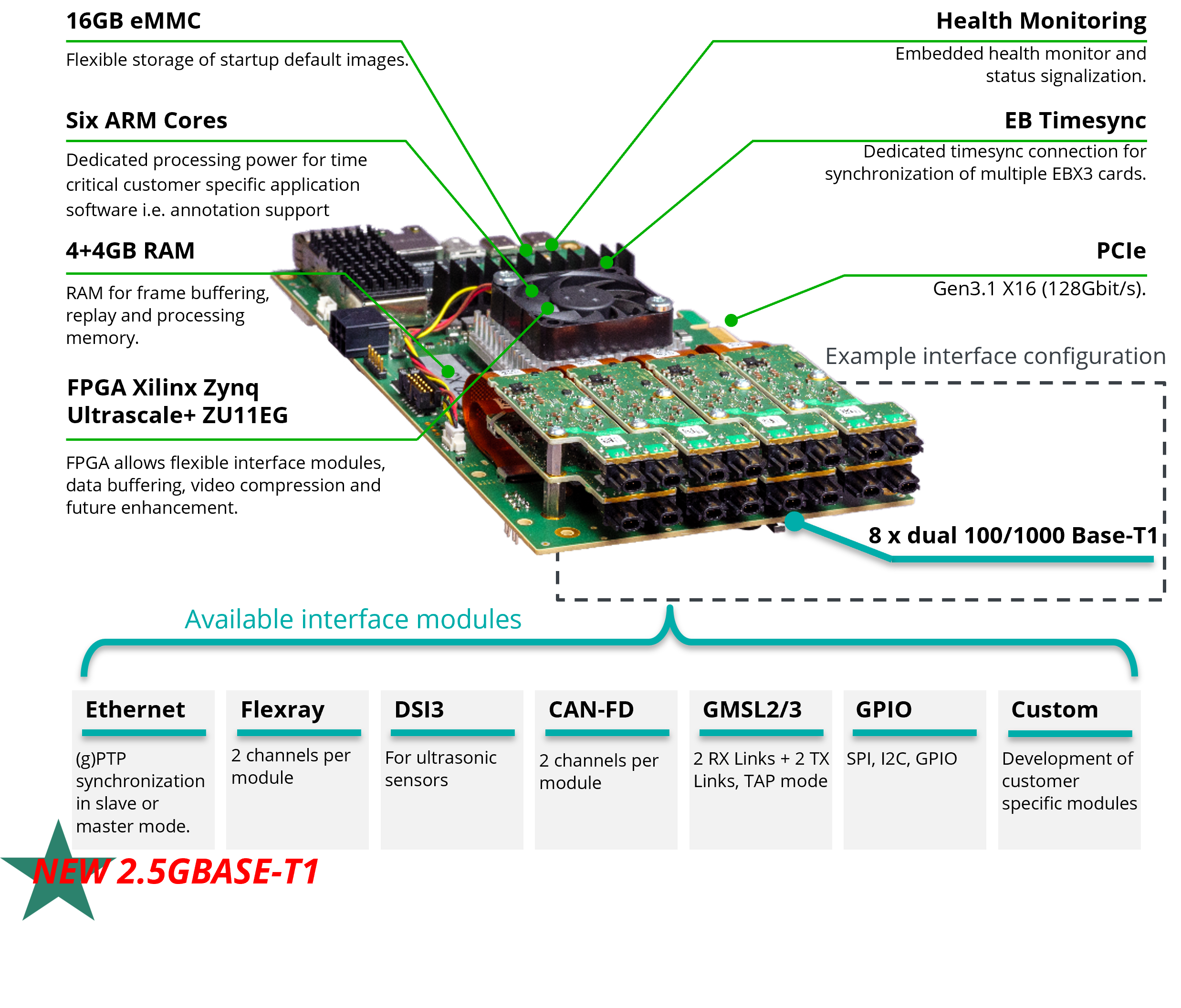

- EBX3 card: Modular system which supports all common automotive interfaces

(2.5 GBASE-T1, Video signals FPDIII /GMSL2/GVIF, CAN-FD,HS/LS, FR, ETH/BroadR-Reach, LIN, DSI-3, GPS) - Flexible and customizable I/O configuration with EB Assist Logger Solution based on your individual requirements

- High-computing performance for data processing and data visualization

- Specific hardware device filters for EB Assist ADTF are available, other platforms on request, ready to use ADTF toolboxes:

Data capturing

Data labeling

Data fusion

Time synced

Error handling

Health monitor (e.g. sensor check)

Signal manipulation

Data compression

Data bluring

- Highly precise time stamping with a resolution of 25ns and better than 1 µs accuracy done with EB Assist Logger Solution

The future of data logging in test drives

ATX solution

Use case

Test drives with development vehicles: capturing and storing sensor data from multiple sources in parallel even under rough conditions

- 6 – 32V DC automotive PSU with Ignition (crank stable, 9 – 32V permanent) up to 1200W

- up to 1024GB 8 Channel DDR4-3200 ECC RDIMM

- 10 SATA SSD, exchangeable

- 7 PCIe Slots with many options pre-qualified (5x PCIe 4.0 x16, 2x PCIe 4.0 x8)

- Storage Extension with up tp 96GBit/s sustained write rate per storage cartridge

- AMD EPYC™ 7002 & 7003 Processors

- 2nd Gen Intel® Xeon® Scalable Processors

- Single Socket SP3 or Dual S3647 Mainboard

- Liquid cooled processors and power supply

- SSD Cartridges up to 60TB (2x per storage extension)

- PCIe Add-ons for additional flexibility

- Support for Multi-CPU/GPU configurations

- -10°C to +60°C full operating (DC Variant)

- Support for Timesynchronization (4x 10G Etherenet) (“XTSS” service from b-plus)

- (g)PTP support for external synchronization

- Timesynchronization of internal PCIe extension cards (like EBX3, EB7200, …)

- GPS

- SIODI: Ignition, Pwr/Rst Button, CMOS Reset, 2x 5V out, 2x 12V out

- Windows or Linux

- 19″

- 4 HE (5.5 HE incl. Storage Extension)

- CE

- FCC on request

+

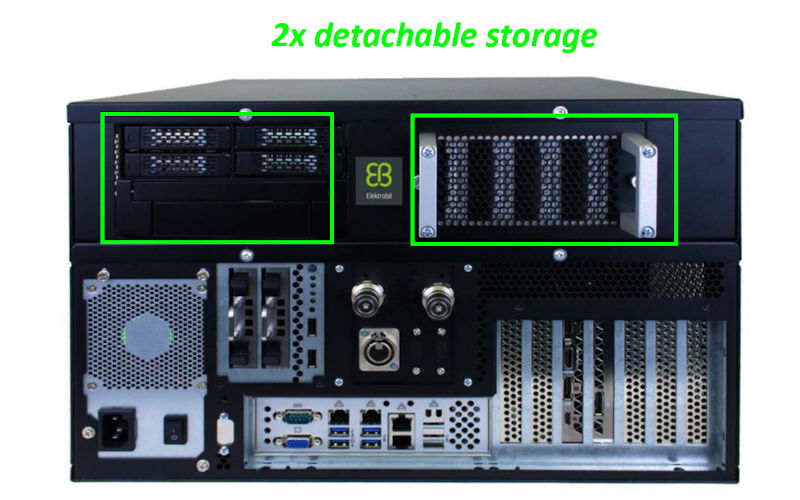

Data logger medium & high variant

Use case:

Test drives with development vehicles: capturing and storing sensor data from high amount of sources in parallel and enhanced storage capacity

- Can be integrated in rack / HiL environment

- Highly-scalable data-logger (e.g. capturing video & bus data / 32x cameras / 8x PCIe Slots)

- 2x NVME / detachable storage: 2x 128TB / 12GB/s

- High performance logger (up to 768GB RAM)

- Can integrate 3rd party measurement interfaces

- AMD EPYC™ 7002 & 7003 or Xeon Intel i10 platforms (B17, B17-vE, B17 -vx)

- 2nd Gen Intel® Xeon® Scalable Processors

- ATX Industry Mainboard

- Air and liquid cooled processors and power supply (depending on variant)

- Support for Multi-CPU/GPU configurations

- (g)PTP support for external time-synchronization

- GPS

- Windows or Linux

- 4 HE (7 HE incl. Storage Extension)

- CE

- FCC on request

+

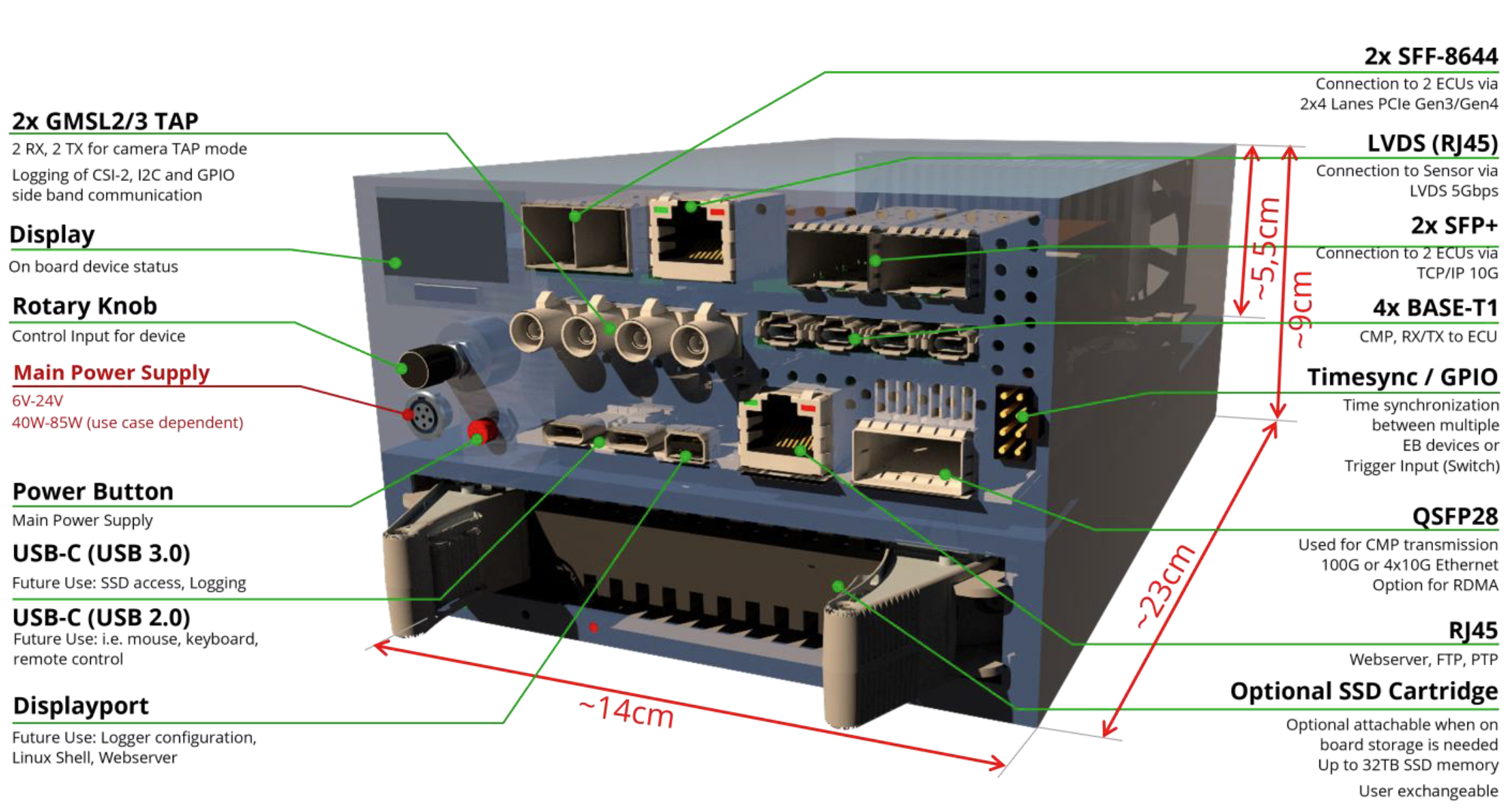

EB Assist future satellite data logger

EBX3 – next generation for Automotive Ethernet & GMSL2/3 CAN, FlexRay, DSI3, SPI (Elektrobit)

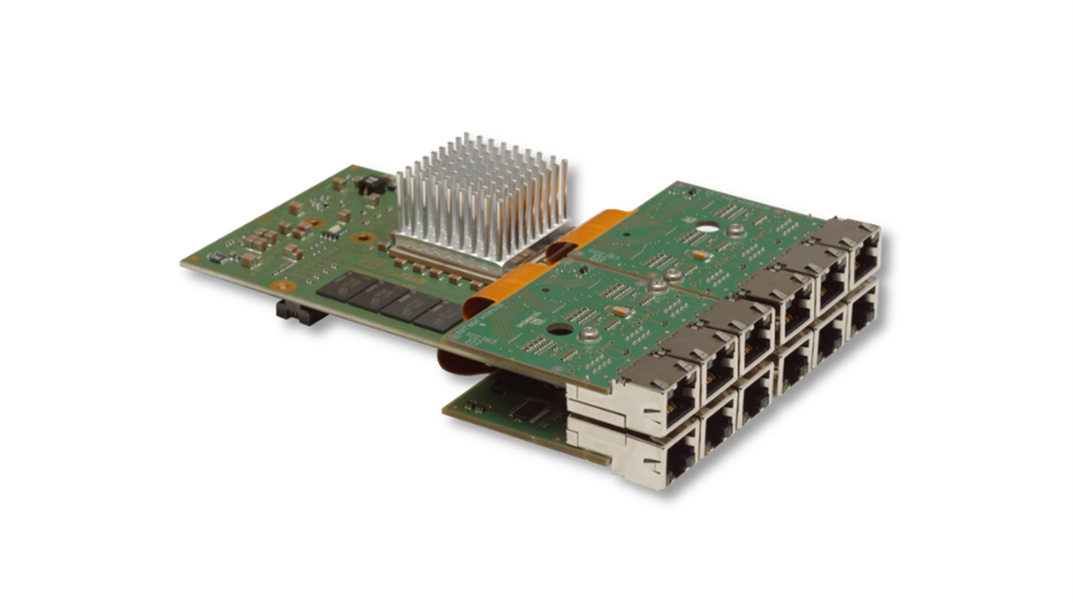

Both systems can be extended with bus measurement cards:

- all with time stamping support

- not all interfaces are currently supported under Linux

- 10GBase-T Ethernet (provided by basic system)

EB7200: 100/1000Base-T1, LVDS3/6G (Continental proprietary) (Elektrobit)

EBX3 boxed CAN, FlexRay, DSI3, SPI, 100/1000Base-T1 & GMSL2/3 (Elektrobit)

Image Solution Box – GMSL2/3, 100Base-T1, GPIO & I²C side channel, 1G/10G Ethernet (Elektrobit)

EB2200: CAN, CAN FD, FlexRay (Elektrobit)

EB8200: 100/1000Base-T1, LVDS3/6G (Continental proprietary) (Elektrobit)

Further information on EB Assist Logger Solution and our automated driving test and validation solutions